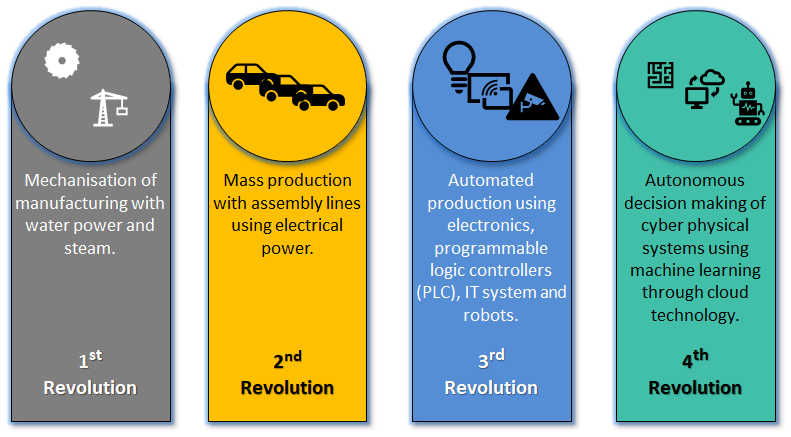

Development of the manufacturing company has progressed to the Industry 4.0 phase. In this case, independent decision-making is used to automate production and reach a new level in terms of quality and capacity control.

This technology is based on smart actuators, big data and cloud services. This development phase has been evolved according to the following trajectory:

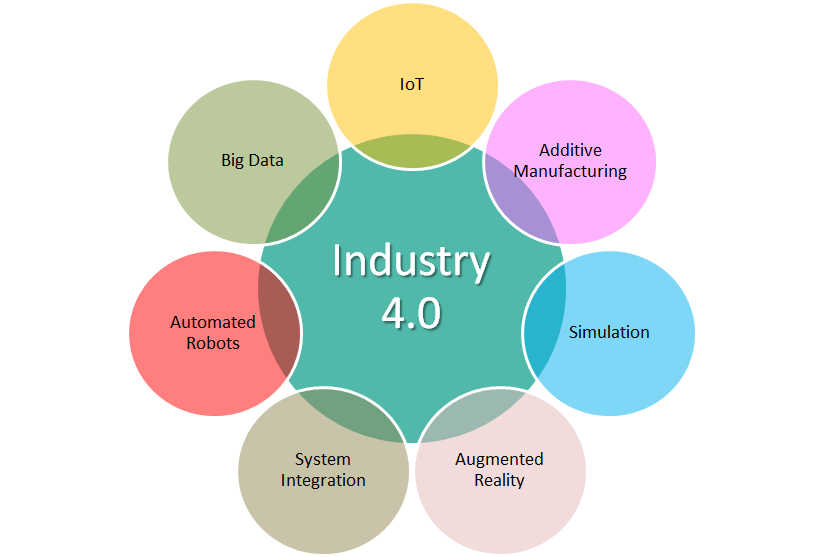

When the devices are capable of advanced learning based on an increasing knowledge base, the production system can be developed on a new footing. IoT enables continuous data collection and large Data collection. Simulations allow different scenarios to be tested before even exporting to production or in production in the selection of different delivery options. Augmented reality (AR) can enhance training or bring new dimensions to the analysis of anomalies and problems.

All of this relies on the effective integration between the various systems, in which case independent equipment and subsystems are in real-time contact with each other.

Industry 4.0 will Revoluton production, but not necessarily overnight, but as the old equipment fleet is replaced with a new one. That is why we need a strategic view that the development of production is in the right direction.

By carrying out careful whole design, we can avoid wasted investments and the use of time for matters that are irrelevant to the whole.